It sure is difficult to predict the “next big thing”. This statement holds true in the realm of paint polishing, too.

It sure is difficult to predict the “next big thing”. This statement holds true in the realm of paint polishing, too.

New technologies, products, and procedures seem to come about inconveniently quick. Just as you’ve got the hang of one new “thing”, along comes another. Try as we might, it’s just not easy to keep up! Better to have to deal with a glutton of advances as opposed to not enough.

We’ve come to accept the random orbital polisher as being a capable alternative to the rotary. Dual mode machines such as the Festool Rotex RO 150FEQ have become relatively commonplace in detail shops and rigs. This is a big deal, considering the prices dual mode machines can command ($220-$500). Interestingly, even the guys that don’t consider themselves to be the most capable detailer in their area nor the most expensive in terms of price understand the inherent value of these machines. They save time, are comfortable to use, and are obviously versatile.

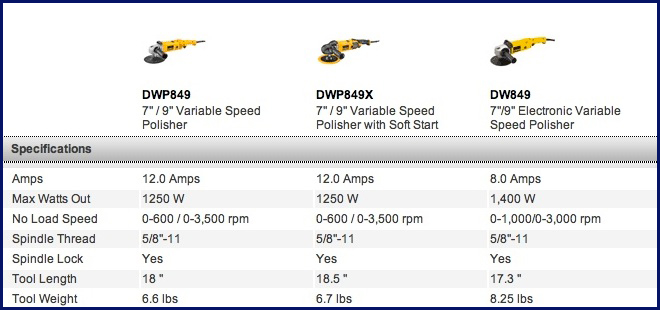

Rotary polishers have become quieter, more comfortable to operate, and lighter to boot. Nowadays, most guys are using slower machine speeds and smaller pads with their rotary buffers, making them easier to manage. Smaller does not necessarily mean less powerful: DeWalt’s DWP series of machines deliver more power and less weight than the original DW849:

I suppose technology is alright, so long as we don’t have to repeatedly spend money to maintain the quality of work we hope to deliver. In regards to paint polishing machines, it’s always wise to buy the one you like. If you don’t know which machine to purchase, ask around, and don’t be afraid to ask to borrow! Or, take a trip to a fellow detailer’s place of business, see how they do things, and fire up a few of their machines while you’re there. Seems to me they might let you help them scrub some stuff, in exchange for letting you handle their favorite polishing machine.